EXTRUSION STEM

The extrusion stem has to withstand the full deformation resistance of the billet. The extrusion loads required produce very high compressive stresses in the stem and buckling in unsupported components. The dummy block does indeed prevent direct contact with the billet and thus high thermal stresses. However, heating by radiation from the liner and by conduction through the dummy block can occur, particularly at the stem tip.

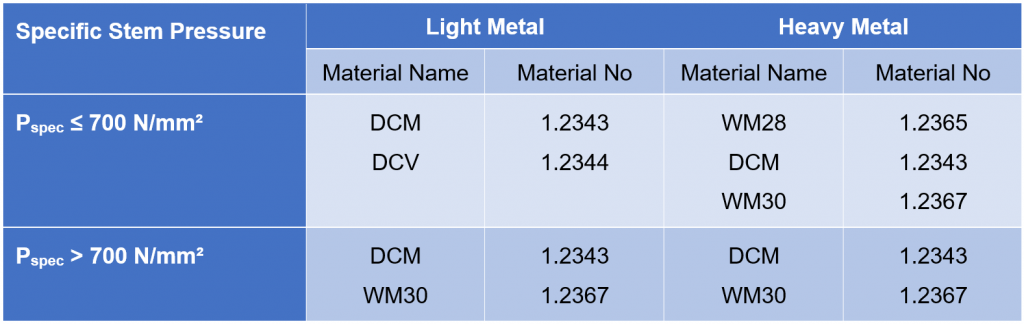

To prevent possible upsetting, high alloy hot-working steels such as 1.2343, 1.2344 or 1.2365 should be used. The tensile strength is in the range 1500-1600 N/mm². The steel 1.2367 is recommended for very high specific pressures (over 700 N/mm²). The tensile strength should then be 1600 to a maximum of 1700 N/mm².