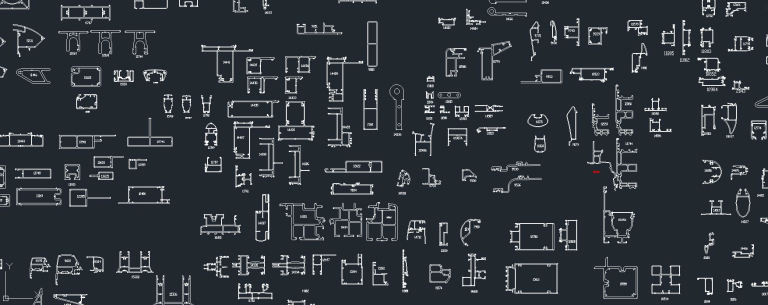

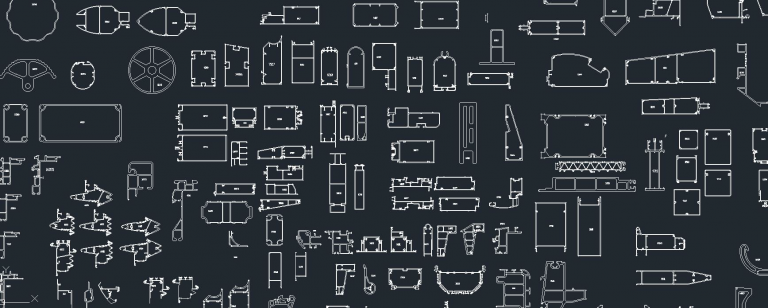

EXTRUSION DIES

The extrusion die is an expensive item subjected to high stresses, temperature and wear during the extrusion process. The performance of the die is critical to the viability of the plant. The contribution of the die manufacturer is to ensure that the die is made to a high standard in terms of both design and machining and that the hot-working steel used is of a high quality and correctly heat-treated. This is the challenge we set ourselves, offering our clients customized and optimized solutions founded on professional know-how.

It is important to have good liaison between the die corrector and the die manufacturer. The extrusion press operator can also make a significant contribution to the success or failure of the die by ensuring that the die and billet are preheated to the correct temperatures, extrusion speeds are matched to the difficulty of the profile, the support tooling is in good condition and the press alignment is within tolerance. Treatment of the die after extrusion also plays a role. Therefore, we complement our efforts in this area through very close collaboration with our customers and their product teams.